CEMMATE PERFORMANCE ENHANCERS (CPE)

Introduction

> Performance enhancer is a second generation of cement additives.

> More and more companies now prefer to use performance enhancers to improve cement quality and reduce clinker consumption.

Values

> Improve mill efficiency.

> Improve particle size distribution.

> Adjust setting time, water demand of normal consistency.

> Improve fluidity and concrete water reducer adaptability.

> Improve bleeding rate.

> Improve pack set index (flowability).

> Reduce recirculation load.

> Reduce blockages in diaphragms and grinds.

> Reduce equipment wear and tear.

> Reduce silo outlet blockages and caking.

> Reduce CO2 emission through clinker replacement.

Benefits to Cement Manufacturers

> Increase mill output by 6%~20%.

> Reduce energy cost per unit of cement.

> Reduce equipment maintenance cost.

> Improve cement transportation efficiency.

> Improve cement quality by solving the following:

> Low quality clinkers

> New requirements from customers and market

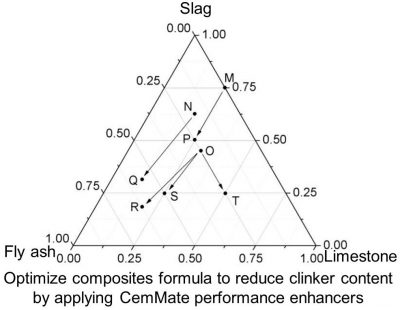

> Improved plant profitability by producing cement with lower clinker content by adding cheap composites such as fly ash, slag, and limestone, but without cement strength drop.

> Increase early strength by 5%~20%, and/or late strength by 5%~20%, so that cement grade can be advanced.