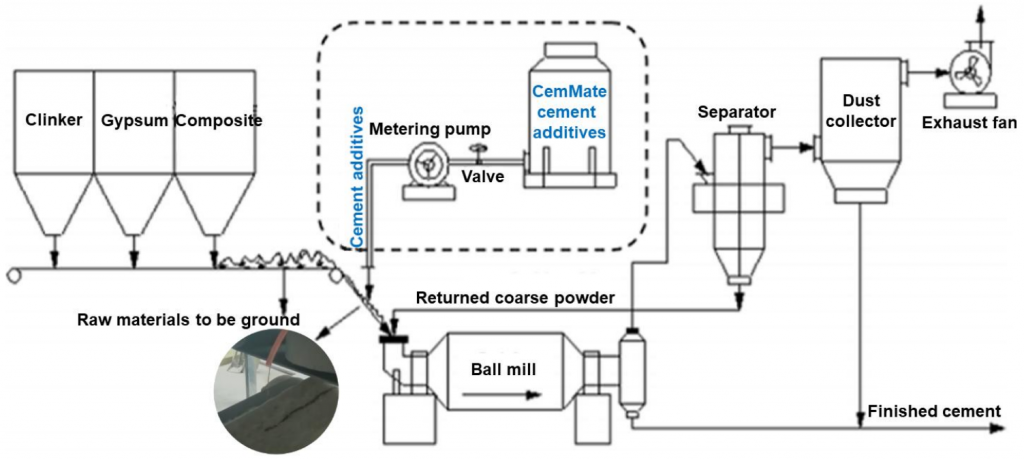

Without changing the existing cement production process, through the metering pump, evenly add customized cement additives to the raw materials on the belt conveyor at the front of mill inlet.

Adjustment method of metering pump

> Preparation: one stopwatch, one volumetric cylinder, one liquid metering pump

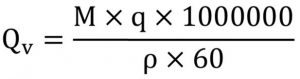

> Start metering pump, calibrate the output volume flow (Qv) of metering pump with stopwatch and volumetric cylinder, and adjust it to ±1ml of the value calculated by formula as below.

Qv—output volume flow (ml/min), M—mill output (t/h),

q—cement additives dosage (percentage of cement quality),ρ—liquid cement additives density (g/cm3).

Points for Attention

> Before applying cement additives into the mill, cement manufacturer’s situation and requirements should be understood, and then prepare customized cement additives and pass the laboratory mini-mill test first.

> The optimum operating temperature in mill is below 80 ℃. If the clinker temperature is too high, cement additives can be added into the composites.

> Ensuring the abundant capacity of the finished cement conveying equipment at more than 30%.

> The separator should be adjusted according to the actual quality control (specific surface area or sieve residue). The ventilation in the mill can be adjusted according to the working conditions.

Package

> 200L/drum; 1000L/IBC tank; flexitank