Raise Cement Plant Profit

CemMate Technology Raise Cement Plant Profit

The application of CemMate additives can realize the following economic benefits.

> Lower the clinker content by ~5%.

> Increase the utilized industrial waste residue content by ~5%.

> Reduce power consumption of cement grinding by ~10%.

For cement plant with annual output of 1 million tons of cement, this will create a profit of ~$1.47 million every year.

According to the calculation of clinker power consumption 45 kW·h/t, standard coal consumption 140 kg/t and cement grinding power consumption 40 kW·h/t, every ton of cement production can be realized:

> Save 7 kg of standard coal.

> Save 6.25 kW·h of power.

> Reduce the consumption of limestone by 65 kg.

> Reduce clay consumption by 9 kg.

> Utilize 50 kg of industrial waste residue.

> Reduce industrial dust by 0.5kg.

> Reduce CO2 emission by 50 kg.

> Reduce SO2 emission by 0.07 kg.

> Reduce NOX emission by 0.08kg.

Customized Additives Solution

PROFITABLE & CONVENIENT SOLUTION TO CEMENT MANUFACTURERS

Customized cement additives in grinding process can show better performance of saving energy, increasing strength, and increasing composites addition rate in the cement, etc than general products, so that customized products can help cement manufacturer create more profit.

Based on the technical principle, cement additives should be customized based on the specific cement raw materials situation and specific requirements of cement manufacturers for cement quality improvement.

Therefore, 10kg-30kg of cement raw materials samples are usually necessary for customizing grinding aids/performance enhancers in the cement additives manufacturer’s laboratory.

However, high international logistics cost of cement raw materials samples and its inconvenience limit the application of the customized products in the international market.

Duyea has developed CemMate technology by mastering the law of various chemical additives raw material’s action on various cement raw materials and developing unique formulation design theory, so that we can supply customized products for customers without conducting laboratory mill test by using overseas customer’s cement raw materials. The process of cooperation with us is convenient.

CemMate Products

> Grinding aids for cement mill

> Cement performance enhancers/cement quality enhancers

CemMate Grinding Aids

CEMMATE GRINDING AIDS (CGA)

Introduction

> It is the a first generation of cement additives.

Values

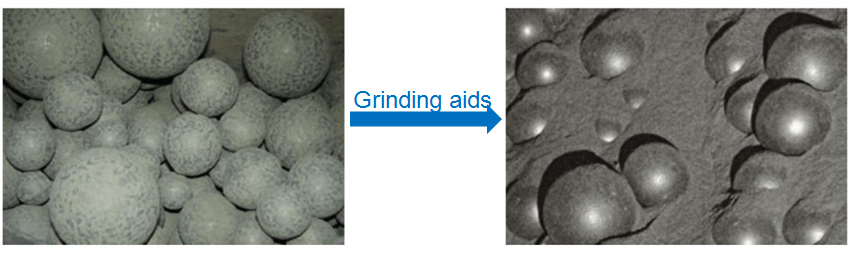

> Improve mill efficiency.

> Improve particle size distribution.

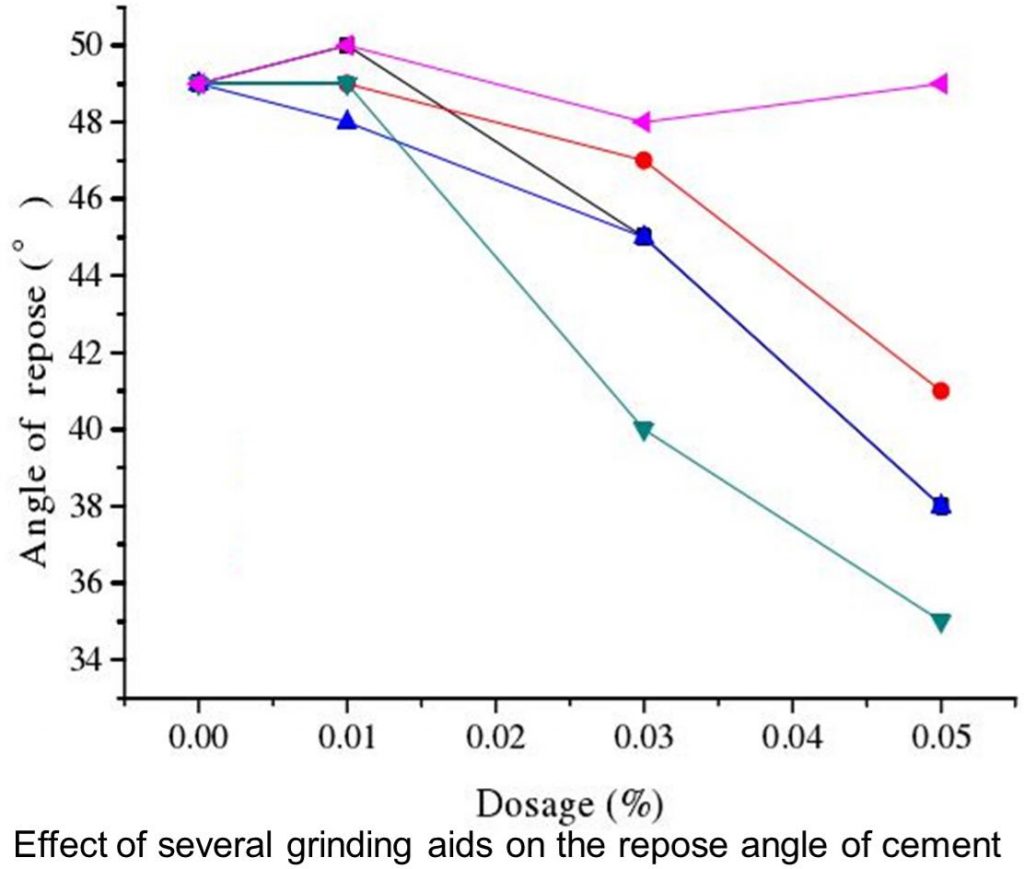

> Improve pack set index (flowability).

> Reduce recirculation load.

> Reduce blockages in diaphragms and grinds.

> Reduce equipment wear and tear.

> Reduce silo outlet blockages and caking.

Benefits to Cement Manufacturers

> Increase mill output by 10%~20%.

> Reduce energy cost per unit of cement.

> Reduce equipment maintenance cost.

> Improve cement transportation efficiency.

CemMate Performance Enhancers

CEMMATE PERFORMANCE ENHANCERS (CPE)

Introduction

> Performance enhancer is a second generation of cement additives.

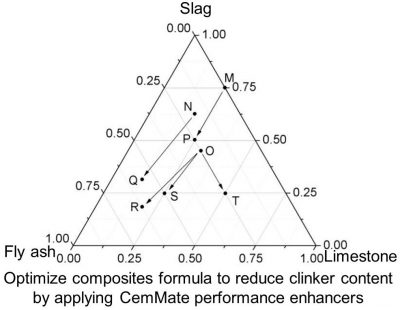

> More and more companies now prefer to use performance enhancers to improve cement quality and reduce clinker consumption.

Values

> Improve mill efficiency.

> Improve particle size distribution.

> Adjust setting time, water demand of normal consistency.

> Improve fluidity and concrete water reducer adaptability.

> Improve bleeding rate.

> Improve pack set index (flowability).

> Reduce recirculation load.

> Reduce blockages in diaphragms and grinds.

> Reduce equipment wear and tear.

> Reduce silo outlet blockages and caking.

> Reduce CO2 emission through clinker replacement.

Benefits to Cement Manufacturers

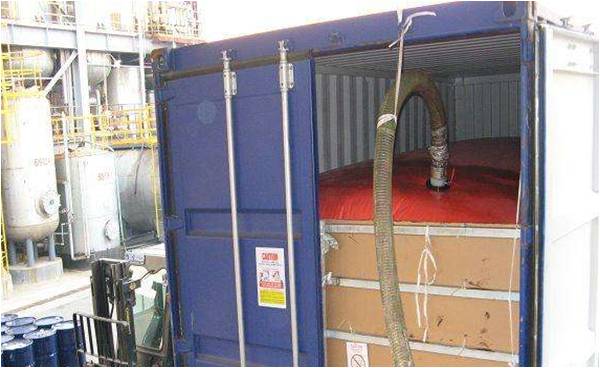

> Increase mill output by 6%~20%.

> Reduce energy cost per unit of cement.

> Reduce equipment maintenance cost.

> Improve cement transportation efficiency.

> Improve cement quality by solving the following:

> Low quality clinkers

> New requirements from customers and market

> Improved plant profitability by producing cement with lower clinker content by adding cheap composites such as fly ash, slag, and limestone, but without cement strength drop.

> Increase early strength by 5%~20%, and/or late strength by 5%~20%, so that cement grade can be advanced.

Application Method

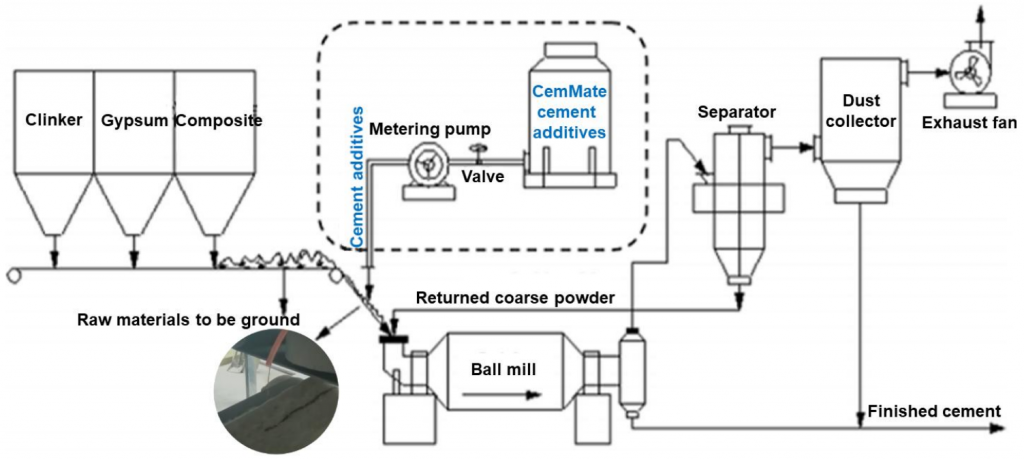

Without changing the existing cement production process, through the metering pump, evenly add customized cement additives to the raw materials on the belt conveyor at the front of mill inlet.

Adjustment method of metering pump

> Preparation: one stopwatch, one volumetric cylinder, one liquid metering pump

> Start metering pump, calibrate the output volume flow (Qv) of metering pump with stopwatch and volumetric cylinder, and adjust it to ±1ml of the value calculated by formula as below.

Qv—output volume flow (ml/min), M—mill output (t/h),

q—cement additives dosage (percentage of cement quality),ρ—liquid cement additives density (g/cm3).

Points for Attention

> Before applying cement additives into the mill, cement manufacturer’s situation and requirements should be understood, and then prepare customized cement additives and pass the laboratory mini-mill test first.

> The optimum operating temperature in mill is below 80 ℃. If the clinker temperature is too high, cement additives can be added into the composites.

> Ensuring the abundant capacity of the finished cement conveying equipment at more than 30%.

> The separator should be adjusted according to the actual quality control (specific surface area or sieve residue). The ventilation in the mill can be adjusted according to the working conditions.

Package

> 200L/drum; 1000L/IBC tank; flexitank

If you have any question, welcome to contact us via sales@cemmate.com.

Benefits calculation

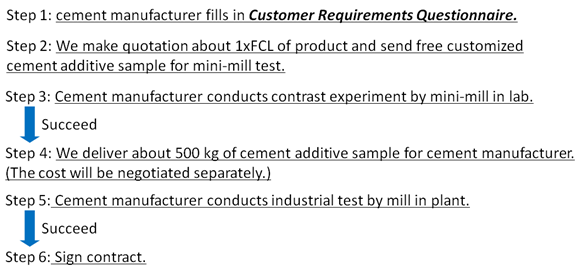

Cooperation Steps

Recruitment agent

In order to make our cement grinding aids benefit cement plants in more countries, our company is currently looking for credible agents worldwide. Our company will offer agent our full support in technical services.

Requirements for Agent

> Familiar with cement plant. Familiar with the product usage and performance. Has a wide range of industry relationships.

> Have good business reputation.

> Strong willingness to participate in this cause, and willing to work with the company to promote the products and provide after-sales service.

> Needs to regularly give feedback to our company on the progress of their work.

Agent Enquiries

Email: cooperation@cemmate.com

Contact us

Duyea Chemical Technology Development (Shanghai) Co., Ltd.

Room 1194, Building 16, No. 79, Fuhua Road, Lvhua Town, Chongming District, Shanghai, China

Email:

General enquiries: info@cemmate.com

Sales enquiries: sales@cemmate.com

Agent enquiries: cooperation@cemmate.com

Customer care: customercare@cemmate.com

Save Money!

97,855,102.01

USD $ has been saved!